In our 3000 m2 factory in Porcia, in the province of Pordenone, we can carry out any type of metal processing: laser cutting, punching, bending, panelling, welding and other additional processes, on sheet metal made from different materials and thicknesses (from 0.6 to 4 mm), with a maximum job scope of 3 m.

The raw material, whether it is stainless steel, ferrous material or aluminium, is just the starting point for us to then develop solutions capable of meeting our customers' expectations, always guaranteeing high performance in terms of technical quality and aesthetic perfection.

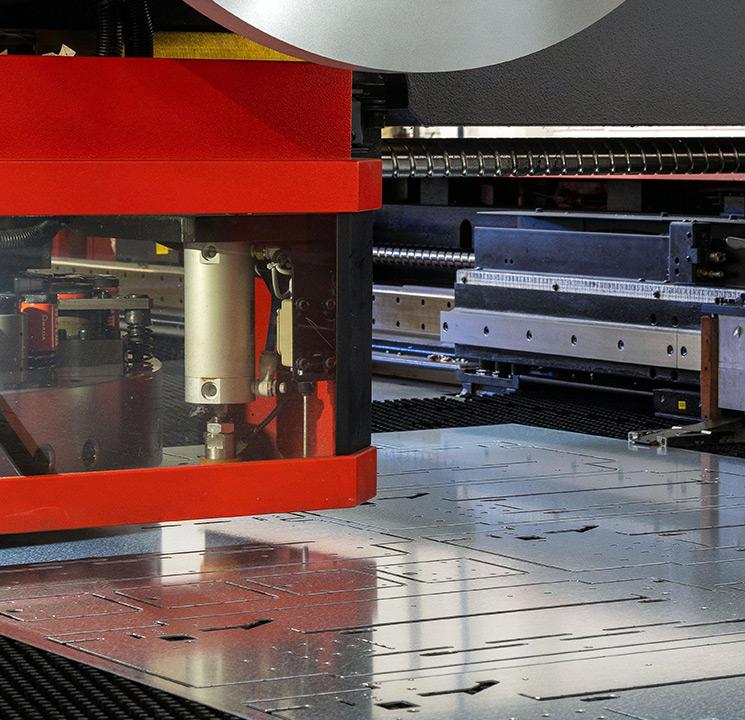

The new Amada EML 2515 AJ combines the benefits of fibre laser cutting and electric punching with an automated loading and unloading system.

Laser technology, now widely used in sheet-metal processing, guarantees optimum cut quality and flexibility in processes with many applications.

Our punching processes allow us to create very unusual shapes in short times and with reduced production costs.

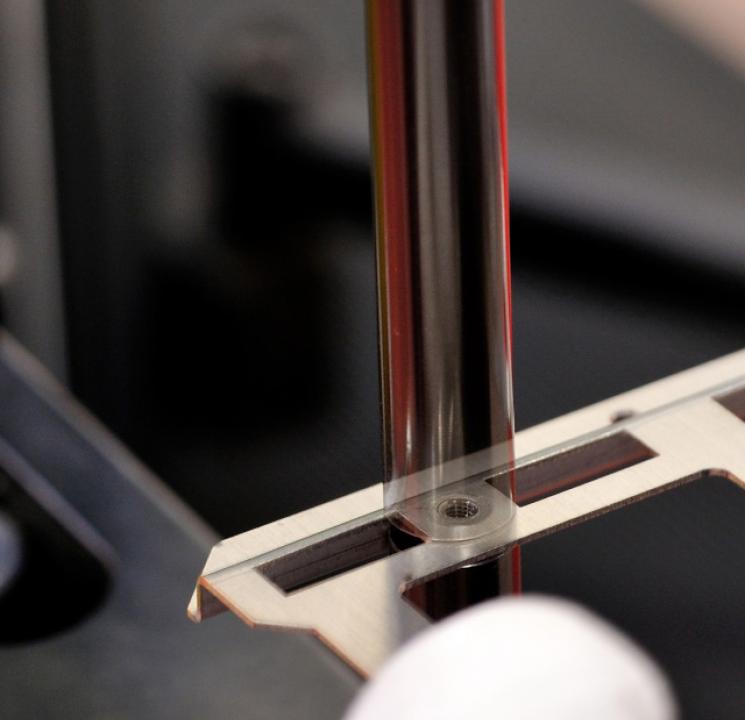

The fact that we own several computer numerically controlled (CNC) bending machines allows us to accurately control the bending angle of each individual piece for a higher quality finished product.

We own a semi-automatic panelling machine which means that we can be versatile and can adapt well to a variety of panel production requirements, ensuring flexible use, speedy execution of the components and precision in developing the bend.

Alongside more technological metal processing, we also offer a sheet-metal welding service.

The packaging of the various components is another of our strong points. It allows us to supply the product required in its final form, saving time and money.

Are you interested and do you want more information?

Contact Us