Our story begins in 1997 when Mauro and Daniele, founded the DM workshop in Porcia (Pordenone, Italy), specialising in sheet metal processing.

Human and financial commitment mark the path of constant growth for our company which enables us today to create integrated medium-light metalwork solutions that are used in different sectors, in Italy and abroad.

Thanks to structured workflows, constantly monitored on board the machine by highly specialised operators, each item we process is the result of a quest for excellence, capable of fulfilling even the most demanding orders, which require the metal components and the relative finishes to be of high quality.

The technical specialisation of our staff combines well with the well-organised logistics of our warehouse, through which the raw materials are coded so that they can be quickly traced.

We are a UNI EN ISO 9001:2015 certified company, guaranteeing manufacturing quality and management that aims to constantly improve company standards and results.

"We give sheet metal personality, creating quality products"

This is the motto that has always accompanied our work and has allowed us, over time, to reach a high level of sheet-metal processing expertise, to create metal components of a very high quality standard.

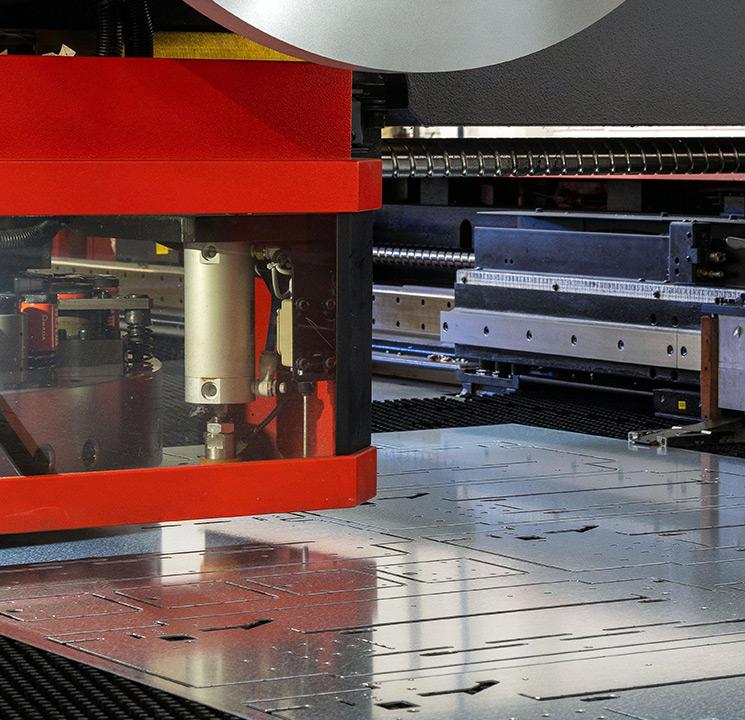

The new Amada EML 2515 AJ combines the benefits of fibre laser cutting and electric punching with an automated loading and unloading system.

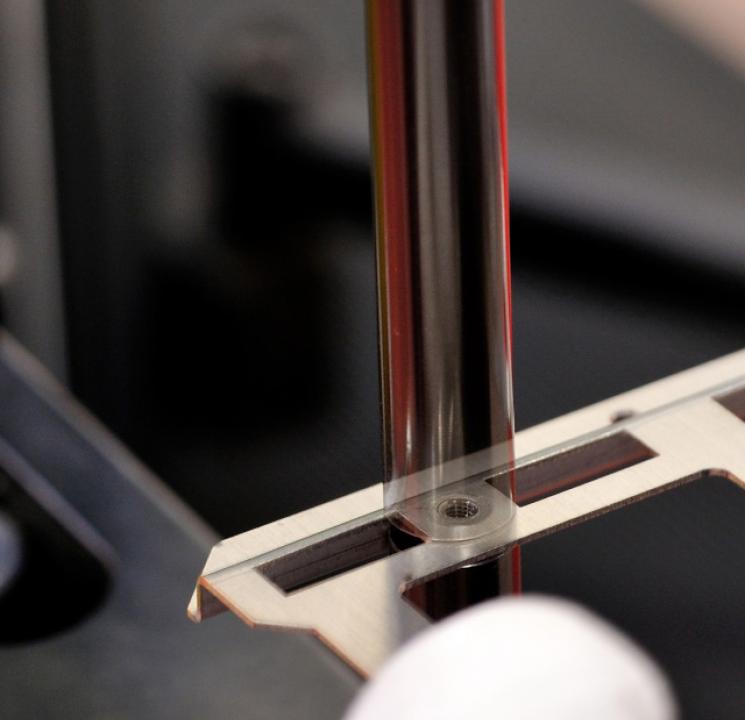

Laser technology, now widely used in sheet-metal processing, guarantees optimum cut quality and flexibility in processes with many applications.

Our punching processes allow us to create very unusual shapes in short times and with reduced production costs.

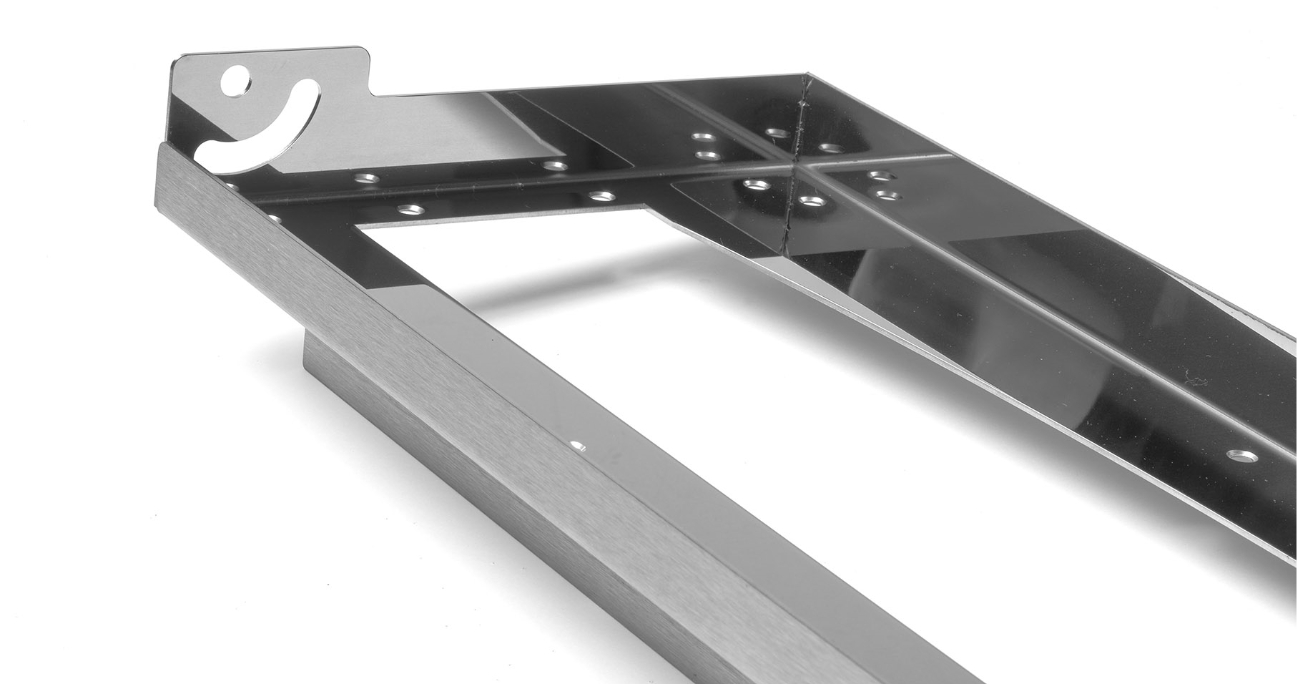

The fact that we own several computer numerically controlled (CNC) bending machines allows us to accurately control the bending angle of each individual piece for a higher quality finished product.

We own a semi-automatic panelling machine which means that we can be versatile and can adapt well to a variety of panel production requirements, ensuring flexible use, speedy execution of the components and precision in developing the bend.

Alongside more technological metal processing, we also offer a sheet-metal welding service.

The packaging of the various components is another of our strong points. It allows us to supply the product required in its final form, saving time and money.